Taikisha Global Group

TKS Industrial Parent Company

TKS Industrial Company is a fully-owned subsidiary of Taikisha, Ltd. a publicly-traded company on the Tokyo Stock Exchange (Ticker: 1979 TYO).

Taikisha makes a large investment in the TKS North American fabrication & manufacturing facility. The TKS Industrial fabrication shop in Columbus Ohio received a $1.5M renovation and equipment upgrade this year, with improvements well underway.

Taikisha partners with major Electronics manufacturer and major Auto OEM to provide a cutting-edge HVAC climate control system at the new battery manufacturing facility in Nevada.

Taikisha Zama develops automated sanding technology for aircraft fuselages, allowing for faster production rates using robots & automation.

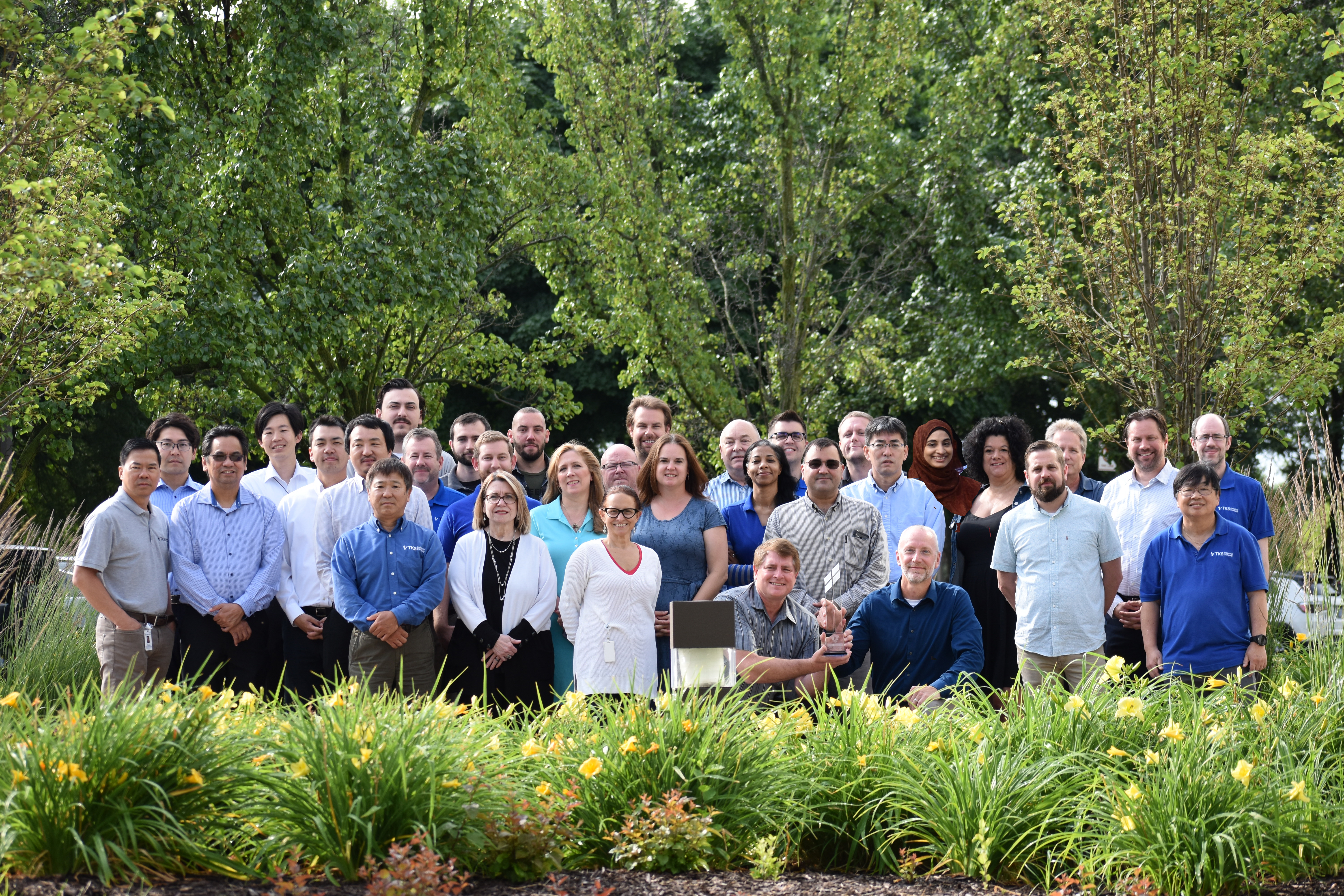

Taikisha Group acquires controlling interest in Encore Automation, an Auburn Hills-based supplier of automation and integrated robotics for paint applications in the Automotive, Aerospace, and more manufacturing industries.

Taikisha Zama leads Taikisha's R&D efforts worldwide.

Taikisha opens brand new R&D facility in Zama, Japan near Tokyo, for advanced robotics and automation for paint systems. Taikisha's new facility features 10+ demonstration cells, showcasing paint application, robotic sanding and finesse, new paint booth technologies, new dry scrubber and new wet scrubber systems, inkjet-based paint application, aerospace fuselage sanding/painting, and new defect detection vision systems.