Conveyor Systems

TKS Industrial & our worldwide Taikisha Group partners offer comprehensive vehicle conveyance systems for paint shops.

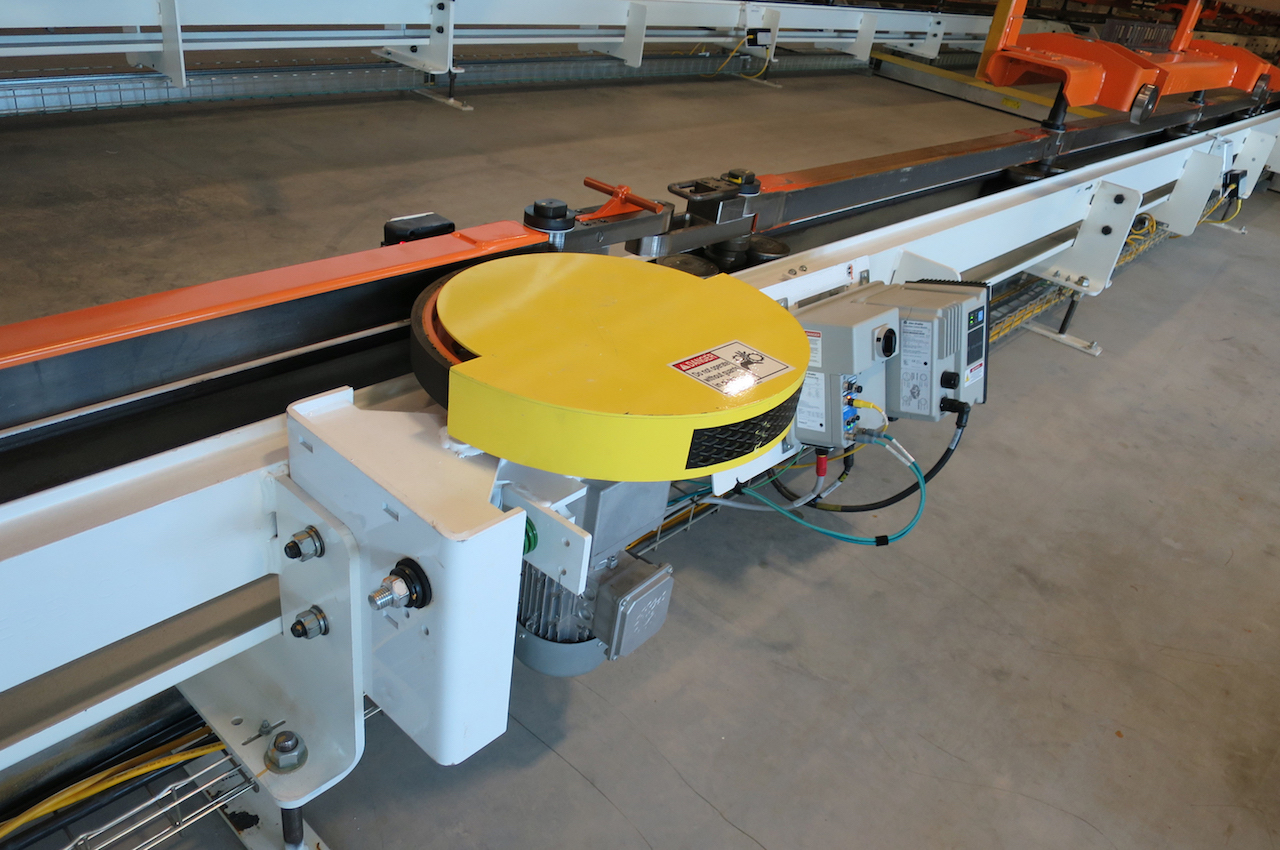

We offer overhead PT/ED & Dip-tank conveyors, floor conveyor, skid conveyor, friction-drive conveyor, power & free conveyor systems.

Paint Shop Conveyors

TKS offers design/build services for conveyor systems to be used in industrial painting systems in the automotive, heavy trucking, aerospace, vehicle, and other industrial manufacturing industries. We have provided conveyors of the following types:

- Floor Conveyor Systems:

- Skid Conveyor with Power Roll Beds (PRB)

- Friction-drive Conveyors

- Inverted Power & Free

- Chain Conveyor System

- Overhead Conveyor Systems:

- Power & Free (P&F)

- Electric Monorail (EMS)

- Dip / Flip Conveyor systems

- Pendulum Conveyor systems

TKS and our partners and Taikisha affiliates have designed and built many turn-key conveyor systems for major Fortune 500 manufacturers, including:

- Automotive OEMs:

- Honda, Nissan, Toyota, VW, Mercedes, Kia, Subaru, Mazda, etc.

- Automotive Tier-1 Parts Suppliers:

- Heartland, Chiyoda, Eakas, Kosei, TOA, DNUS

- Aerospace:

- Boeing

- Heavy Trucking / Semi trucks:

- Hino Motors, Navistar, and more US-based Semi-truck manufacturers.

- Motorcycle:

- Harley Davidson

- ATV/UTV/4x4/SxS - recreational vehicles:

- Honda, Polaris, Suzuki, Kawasaki, etc.

TKS builds primarily vehicle body handling conveyor systems, used in the Automotive industry for painting and curing vehicle bodies and truck cabs. We also offer conveyor systems for parts painting and handling, including bumpers, fascias, plastic parts, spoilers, mirror caps, and more. We also provide conveyor systems for other industries, including Aerospace, Heavy Trucks, Motorcycle, RVs, ATVs, and other vehicle-related manufacturing industries.

Learn more about the entire Paint System

Dip Tank Conveyor Systems

There are several variations of dip conveyor system:

- Overhead Power & Free

- Electric Monorail Systems (EMS)

- Pendulum Conveyor systems

- Rotational Conveyor Systems

A TKS conveyor system offers the following benefits:

- Modularity: Use pre-engineered TKS conveyor modules to build any size system you need. Engineered modules with common interfaces allows for standardized products and quick manufacturing, while providing nearly unlimited flexibility for paint system design and layout.

- Scalability: Easy to add on new conveyor sections during cap-up phases.

- Choose between continuous moving line conveyors or an indexing conveyor system with fast-in, fast-out of hold positions to provide more process time.

- Process flexibility: by skipping processes, it allows you to create different cycles.

- Product flexibility: the system adapts to the type of body.

- Simple maintenance: standardized components reduces pare parts needs.

- Compact dimensions: reduce conveyor footprint.

- Possibility of storing the skid or carriers (strip out trolley) during the process.

- Ensures high process quality by minimizing the immersion of the conveyor surface in the process baths.

- Adaptable: Suitable for implementation without the use of skids. Can be direct conveyor to body.

- Reduction of energy consumption in addition to a reduced initial investment.

- Use of standard plug-and-play components.

- Control: speed of conveyor can be adapted to specific customer requirements to meet process timing needs.