Paint Spray Booth

TKS Industrial offers several innovative paint booth designs for paint spray application.

We offer paint booths, spray booths, wet scrubber paint booths, dry scrubber paint booths, and dry filter paint booths.

Turn-key Paint Booth

TKS offers design/build services for custom paint spray booths for many industrial manufacturing industries.

We have built paint booths of the following types:

- i-Dry scrubber cardboard filter dry booth

- down draft paint spray booth

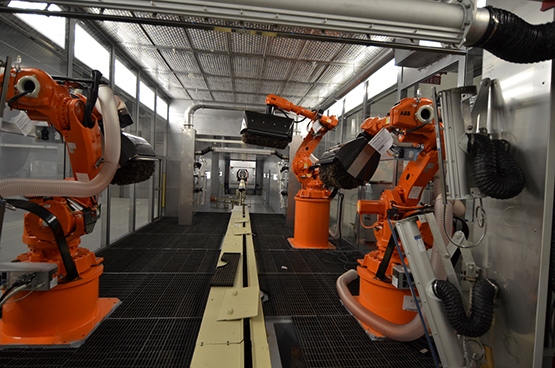

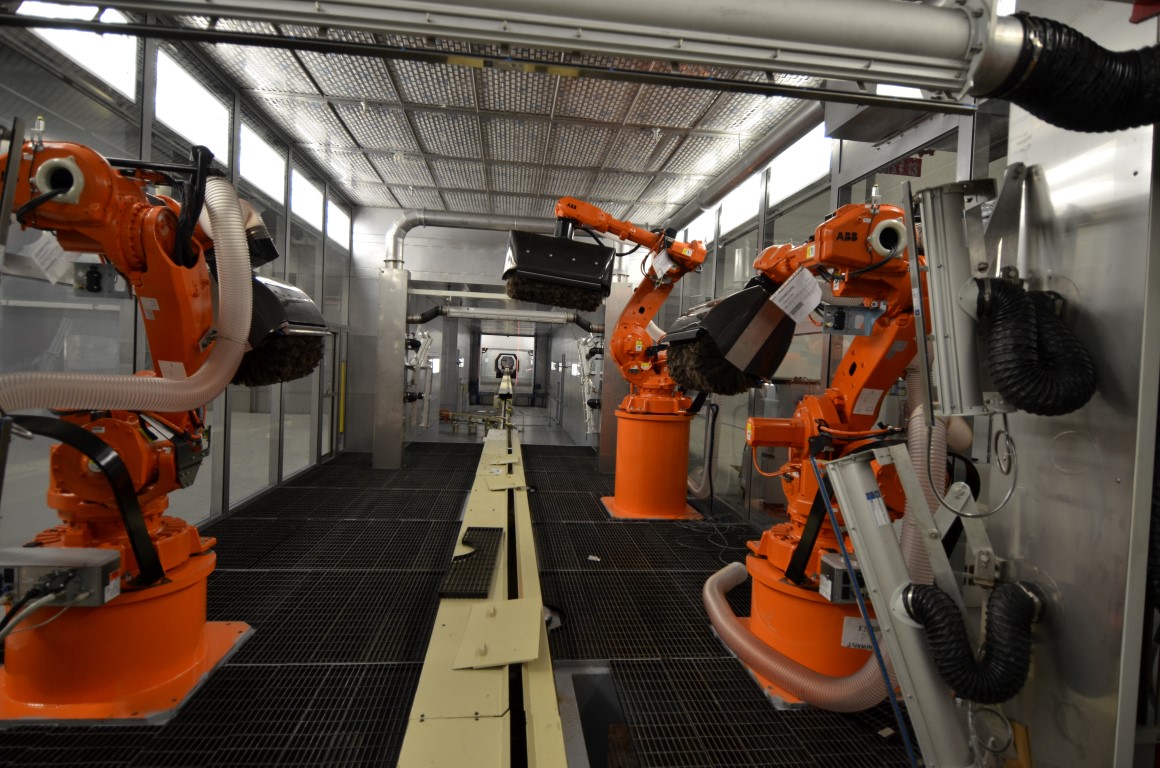

- robot paint booths

- manual paint booths

- wet scrubbers

- dry scrubbers

- And more.

TKS has designed and built paint spray booths for major Fortune 500 manufacturers, including:

- Automotive OEMs:

- Honda, Nissan, Toyota, Kia, Subaru, Mazda, etc.

- Automotive Tier-1 Parts Suppliers:

- Heartland, Chiyoda, Eakas, Kosei, TOA, etc.

- Aerospace:

- Boeing

- Heavy Trucking / Semi trucks:

- Hino Motors, several US-based Semi-truck manufacturers, etc.

- Motorcycle:

- Harley Davidson

- ATV/UTV/4x4/SxS - recreational vehicles:

- Honda, Polaris, Suzuki, Kawasaki, etc.

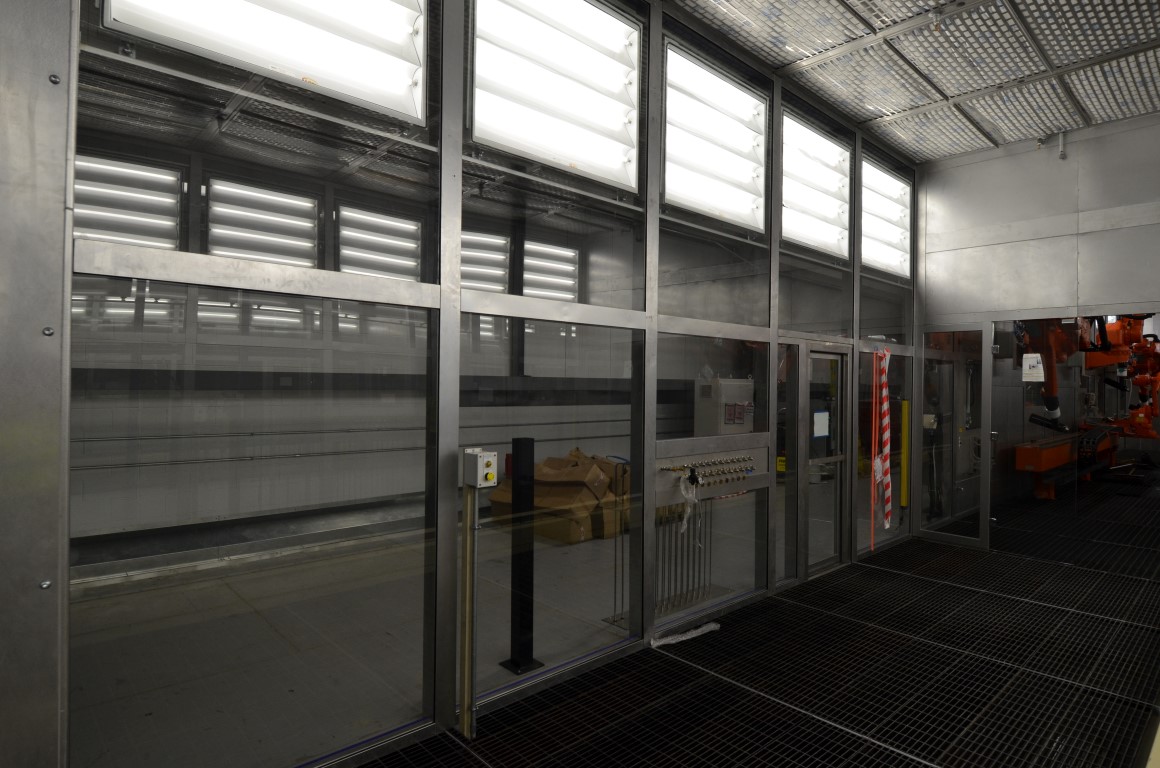

TKS builds primarily downdraft-style paint spray booths, used in the Automotive industry for vehicle body spray painting using robots/automation or manual application. Our paint booths may also be used in the Aerospace, Heavy Trucks, Motorcycle, Parts suppliers, and other vehicle-related manufacturing industries.

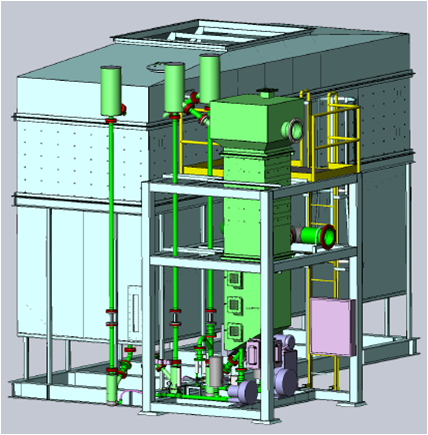

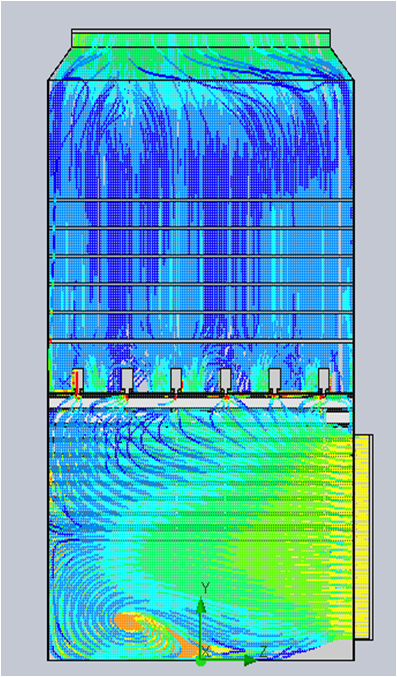

A paint spray booth consists of three main sections:

- The top section is the plenum, an open area where the supply air ducts deliver the fresh and/or recirculated air. The plenum typically contains one or more rows of filters that the fresh air must pass through before reaching to main booth area. This ensures clean air in the booth. TKS installs roll-type filters to keep the booth pressurized and provide an even downdraft.

- The middle section is the paint spray chamber, where the vehicles or parts travel through and the actual paint application takes place. This section contains a conveyor through the middle with grating for the paint overspray to pass through to the lowest section. Some TKS booths use retractable grating to reduce maintenance and cleaning required.

- The bottom section of the booth is the scrubber, which captures the paint overspray. There are several types of scrubber sections, including a wet scrubber using water, a dry scrubber using limestone powder, or a dry filter which uses cardboard, paper, and fabric filters to capture the paint overspray.

Learn more about the entire Paint System See completed Paint Booth Projects

i-Dry Scrubber Cardboard Filter Dry Paint Booth

TKS offers our unique horizontal cardboard filter underbooth technology, used to capture paint mist overspray.

Paint Booth Scrubber Types

A paint booth can utilize one of three main types of scrubbers:

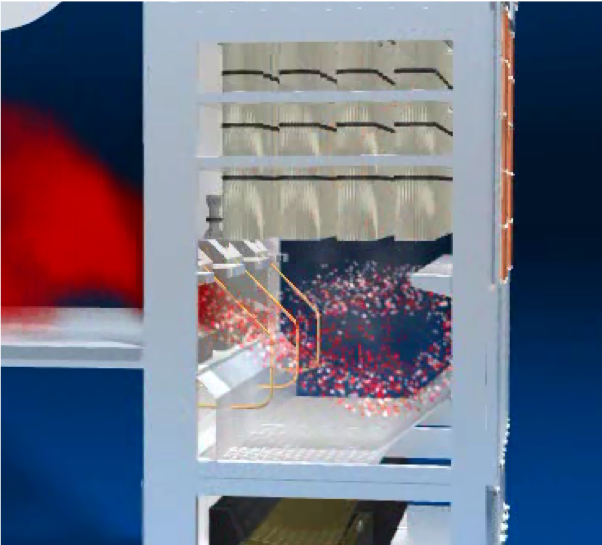

- Dry Filter (i-Dry): There are several varieties of dry filter booth, depending on the amount of paint to be sprayed in that zone. A heavy-use dry filter spraybooth may feature up to three different layers of paint capture filters, starting with large-gap paper filters, next using a fiber-based bag filter or pocket filter, and finally utilizing a 99% HEPA filter to catch the finest particulates. Dry filter booths are the simplest type of paint spray booth, but they are susceptible to clogging quickly if the paint applicator has a low transfer efficiency (lots of overspray).

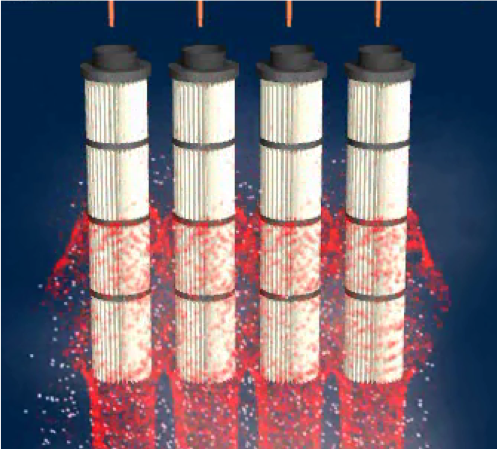

- Limestone Dry Scrubber (DrySpin): A recent development in paint spraybooth scrubber technology, the dry booth features a limestone-based paint capture system. The super fine limestone power mixes with the wet paint overspray and then collects on a 99.9% effective filter. Periodic pulses of air will knock the limestone/paint mixture off the filter and down into a collection hopper. The primary advantage of the dry booth type of paint booth is the reduced humidity during recirculation of air. This requires less reconditioning of the air (a little cooling only) and saves significant energy.

- Wet Scrubber: the most common type of scrubber, it utilizes a flooded water pan underneath the spray zone to capture paint overspray mists. The water catches the paint particulate and conveys it to a paint sludge treatment area. The underbooth section includes a mist eliminator as well, which separates the water/sludge mixture from the air stream. Historically, most high-production paint spray booths have used wet scrubbers either with a wet wall or a wet flood sheet capture. TKS offers many varieties of wet scrubbers, including Taikisha's newest S1-type wet scrubber, first installed in 2019.

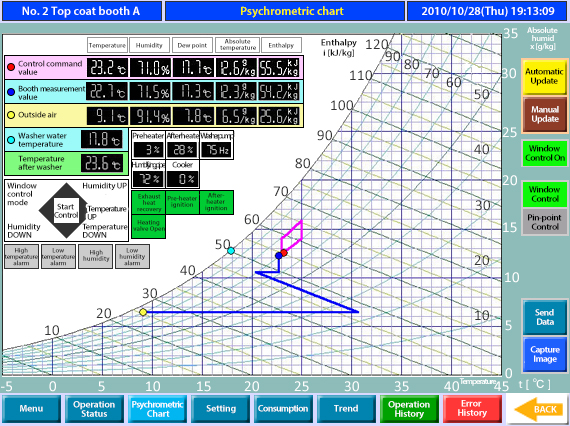

Nearly all paint booths use a paint robot to apply the paint to the vehicle. Most robot zones will heavily recirculate the air to save energy by reconditioning less air. A recirculation or recycle air supply house (RASH) is used, with a portion of the air (10-20%) being exhausted: sent to a thermal oxidizer or VOC abatement equipment. Fresh air is provided to make up the 10-20% exhausted.

Paint Spray Booth Installations & Customers:

Currently in use at:

- Honda: Eight (8) Installations

- Toyota: Twelve (12) Installations

- Nissan: Nine (9) Installations

- Kia: Two (2) Booths

- Subaru: Two (2) Paint Booths.

- Mazda: One paint booth installation.

- Harley Davidson: Two (2) booth/oven projects.

- The Boeing Company: One (1) booth project

- Heartland & Chiyoda: Three (3) booth projects.

- Peterbilt: One (1) booth project.

- Navistar: One (1) booth project.

- EV OEM: One (1) booth project.

Heated Flash-off Tunnels between Paint Spray Zones

In a 3-wet paint process, the prime, base, and clear coat paint layers are applied without a full cure oven in between. A short heated flash-off (HFO) tunnel is used in between the paint booth zones to flash off the liquid solvents in the top layer of the paint so the paint layers do not intermix. Parts are then cooled before the next spray zone.

Fully automated limestone powder load/unload

The limestone used in the under booth scrubber system is fully automated: pneumatically conveyed from an outside silo with fresh limestone power, via piping to the underbooth's fresh powder hopper. Once the limestone powder is spent, it's again pneumatically conveyed to another outside silo with spent powder, to await pick-up for recycling.

TKS Dry Filter Booth Disposable Filters

The TKS Dry Filter booth uses three sets of paper and fiber filters to capture the paint overspray and particulate. These filters may be recycled via a waste-energy program, burning the cardboard and the paint solvents to power an electric turbine. The dry filter scrubber system reduces the number of moving parts vs a traditional wet booth or limestone booth, so there's fewer pieces that can break.

Automated Feather Duster System

Encore Automation offers a top-of-the-line automated feather duster system at the entrance of the coating booths. We source and assemble the ostrich feather rolls in-house to ensure quality. The automated feather dusters are equipped with a vacuum system to pull off any debris, dust, or dirt picked up - allowing for continual operation without any maintenance needed.

Increased Reliability

No shutting down production due to paint booth issues. TKS sources only the highest quality Air Supply Houses, Fans, Coils, and other key components. Our proprietary PLC climate control system ensures continuous operation offering precise temperature and humidity in the booth, even with rapidly changing outside temperature and humidity conditions.

Reduced CO2 and NOX Emissions

Up to 80% reduction in CO2 emissions from the paint booth.

Automotive

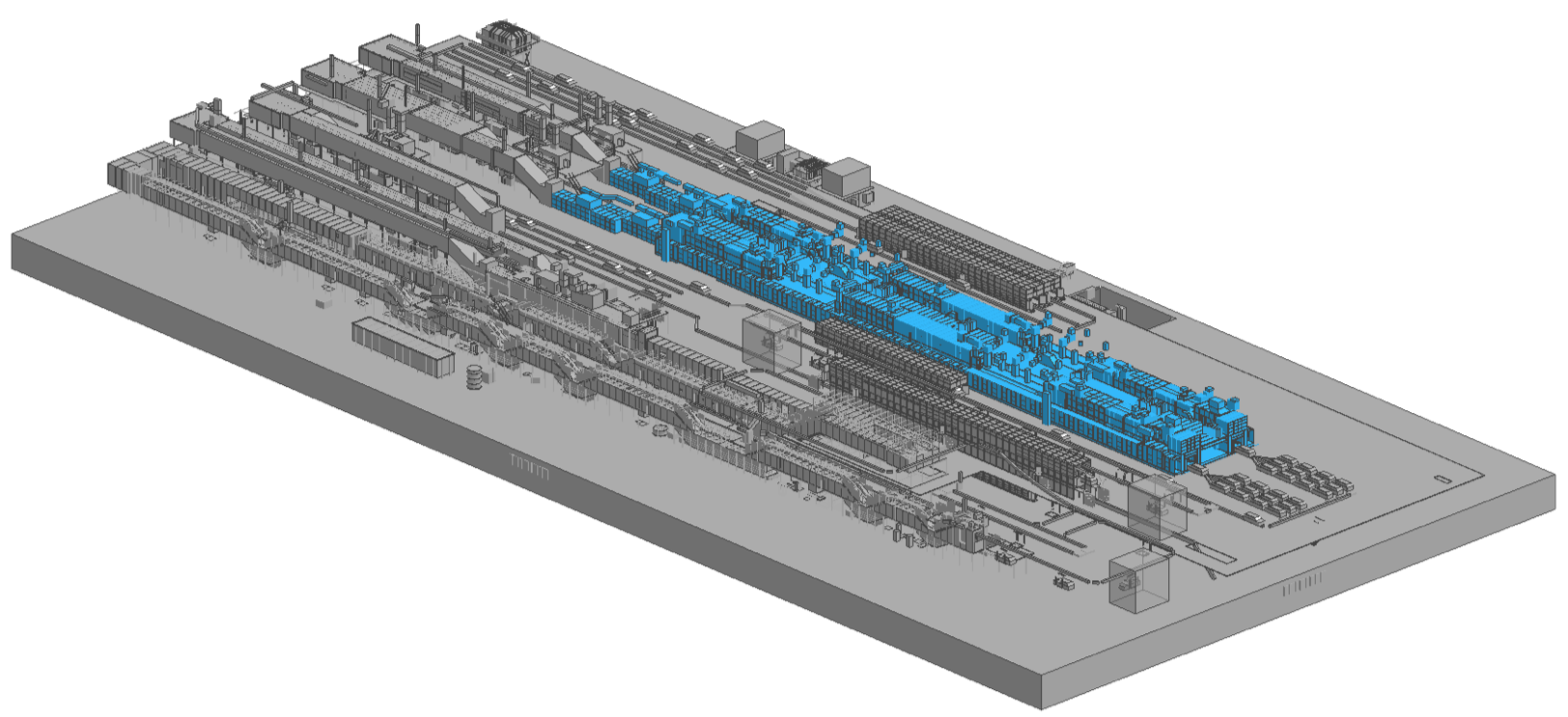

TKS has installed over 100 paint spray booths for the Automotive industry in North America since 2000. Pictured here are parallel topcoat spray booths being installed in a new Automotive paint shop. TKS will engineer, design, fabricate, install, and commission these booth systems with a complete turnkey package.

Small Parts Production

TKS offers turn-key paint systems for small parts and component production for Automotive, Aerospace, Motorcycles, RVs, ATVs/UTVs, Semi Trucks, and other recreational vehicles.

Heavy-duty Trucks and Semis

TKS builds complete paint shops, including paint booths and ovens for the commercial van, heavy-duty truck, and semi-truck markets. The paint process includes automated sealer, under body coatings (UBC), liquid-applied sound deadener (LASD), and stone-guard / PVC anti-chip coatings (SGC).

Encore Automation, subsidiary of TKS Industrial

TKS offer in-house robot design and simulation for spray booth layout. Encore Automation has installed over 1200 paint robots for many customers including FCA, GM, Harley Davidson, Fender Guitars, and more.

Reduce Paint Booth Energy Usage

The industrial paint systems use the most energy in an Automotive plant. TKS offers energy use reductions up to 80% over traditional wet booths with 100% fresh air. Recirculated dry booth offer significant savings with lower energy usage.

Frequently Asked Questions

About TKS Paint Spray Booths

We have fabricated paint spray booths out of Stainless Steel (304 or 316), aluminum-coated steel, galvanized steel, glass panels, and more. We can fabricate a custom booth to your material specifications.

Most spray booths we manufacture are a custom length, sometimes custom width and height, so it's hard to provide a general cost. There's a quite a big difference between your simple single unit spray booth, and a large, multi-layer, 60-JPH high production paint booth for Automotive plants. Contact us today to get a custom quote.

Most booth sections are 18'-20' wide, with lengths depending on the required production rate. Floor loading depends on if robots are used and how many robots per area. Booth height depends on the type of booth scrubber used, required spray height, and plenum height which is typically a function of downdraft rate.

Our paint spray booths have been installed over 100 times since introduction at 10+ different Fortune 500 companies.

Paint Shop Layout with Spray Booths Highlighted:

TKS Offers

Worldwide Installation and Service

Turn-key Equipment Installation

Let TKS handle every aspect of your project from start-to-finish.

Annual Booth

Balance Assessments

TKS offers monthly, quarterly, and yearly paint booth health check assessments to evaluate performance, downdraft rates, booth balance, and perform critical preventative maintenance tasks. Let the paint booth experts handle the maintenance for you.

Purchase New Systems

Ready to purchase a new paint booth or entire paint shop? We're here to help with quick turnaround times.

Troubleshoot Equipment

Having a problem with your paint spray booth? Our booth experts and engineers are always available to help.

Pay-by-the-day consulting services

Need an engineer to come to your plant location to help for the day? No problem. Our engineers are available to help out for a minimal daily fee.

Access to TKS Engineering Team

If you need help, advice, or expertise, the TKS Engineering team is always available to assist our customers.