Automation & Robots

TKS Industrial is a distributor for Encore Automation, offering innovative Automation & Robotic systems for paint spray application.

We offer paint robots, spray applicators, sealer robots, automated defect detection, automated finesse, robotic sanding, polishing and more.

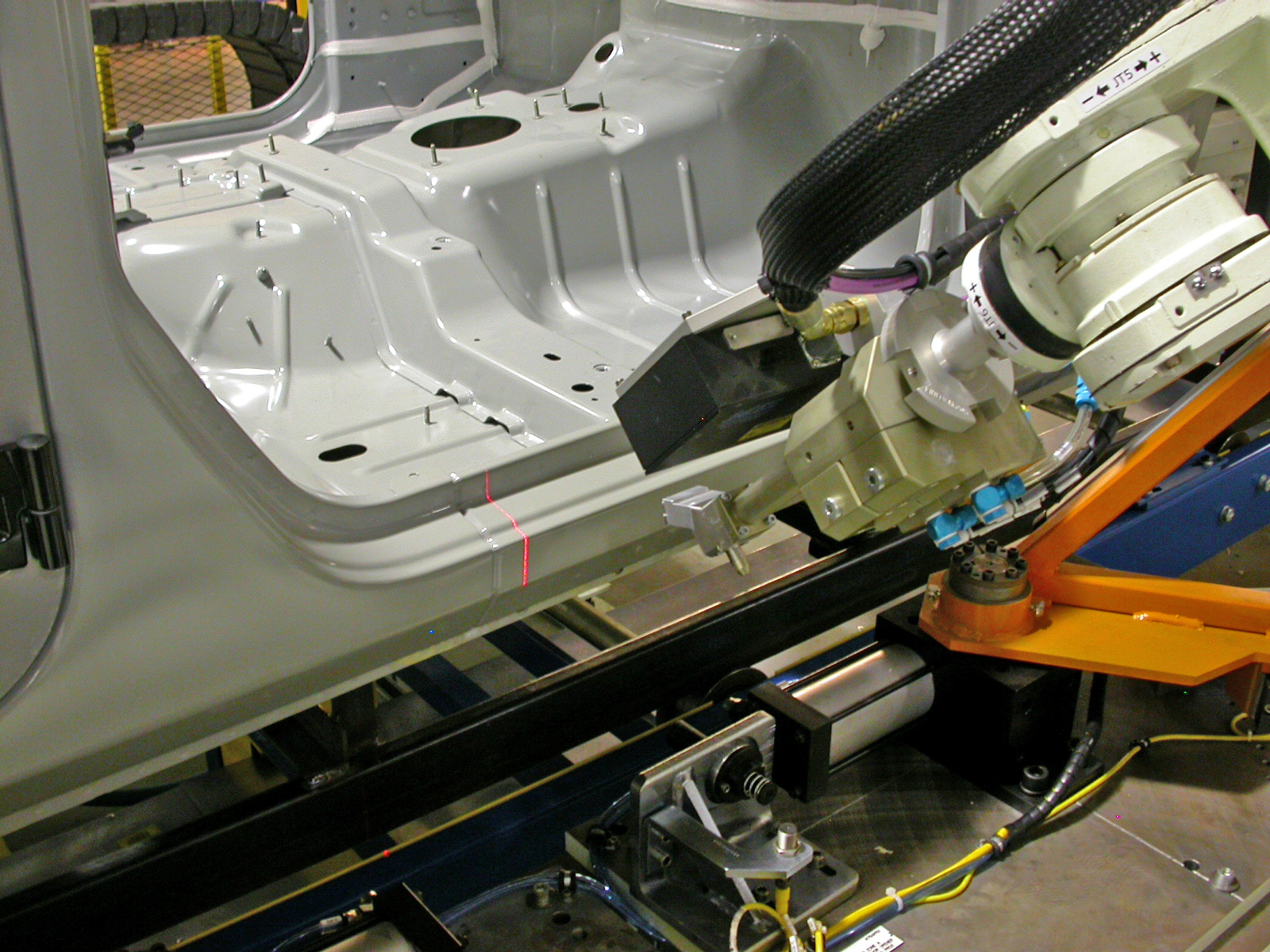

Paint Spray Robots

TKS's wholly-owned subsidiary, Encore Automation, offers liquid paint spray robots and powder coating systems. TKS is a distributor of Encore Automation products, services, and systems. TKS & Encore have experience with:

- Many Application Materials: Solventborne and Waterborne Primer, Basecoat and Clearcoat, and Multiple Component (2K) Paints.

- Paint Applicators: Electrostatic Gun or Electrostatic Rotary Atomizer, Direct Charge Waterborne Applicators, and Air Atomized Guns

- Various Application Equipment: suppliers including Sames, ABB, Durr, Carlisle, and all major brands.

- Paint Robots and/or Paint Machines: suppliers include Fanuc, ABB, Kawasaki, and all major brands.

- Encore Automation has system knowledge and experience to optimally specify, configure, layout, simulate, engineer, design, assemble, test, install, commission, process, tune, and provide training and service on systems for the above applications and materials for using many of the above equipment options.

Encore Automation has integrated and installed paint robot systems for major Fortune 500 manufacturers, including:

- Automotive OEMs:

- Honda, FCA, General Motors

- Aerospace:

- Boeing, Embraer, Honda Jet

- Motorcycle:

- Harley Davidson

- Others:

- Fender Guitars

Encore Automation is an award-winning integrator of robotics and automation systems. Encore was awarded Fanuc's integrator of the year in 2016. But they have the expertise and ability to integrate any combination of robots, applicators, paint supply, in any combination of brands or systems. We will work to your specification to provide each manufacturing plant with the type of equipment they desire. TKS offers the ultimate brand flexibility and our recommendations won't be trying to push our in-house product. We'll always recommend the best combination of equipment and systems for your job.

Learn more about the entire Paint System See more on Encore's site

Paint Surface Preparation

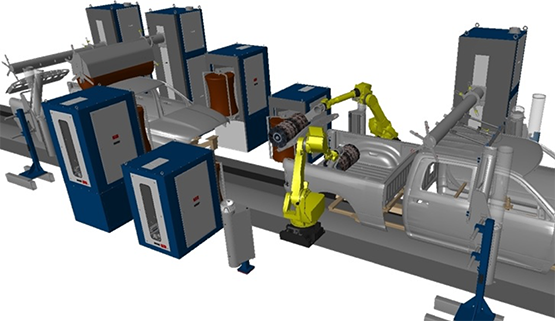

Prior to the paint booth, Encore offers several types of surface prep and cleaning systems, including automated feather duster, blow-off, sanding/buffing (wet & dry), and water blast systems.

- Automated Feather Duster: Using Encore engineered and designed standard machines and robot mounted assemblies Encore offers an extensive assortment of custom feather duster systems for a wide variety of vehicle and product sizes. Current systems range from full robotic feather dusters with optional integrated hoods to floor mounted hood assemblies. Encore standard single column articulating machines can be provided in clean wall or in booth design with servo controlled articulating axis or manual adjusted fixed machines. A combination of both robotic and fixed machine feather dusting systems can offer the most flexible design for complex requirements. Encore also offers a unique hoodless truck box interior robotic feather duster. Removing the hood allows the feather rolls to get into areas which would be inhibited by the presence of a hood. Instead a fixed hood is mounted alongside the robot allowing the rolls to be cleaned between boxes. Encore also manufactures in house all the Ostrich feather rolls for the Encore systems as well as any replacement feather rolls for existing feather duster systems.

Some of the features in Encore standard product solutions include:- All bearings are sealed for life

- Multi axis servo motors with intelligent drives

- Integrated resolvers for accurate position feedback

- Monitoring of the de-static bar

- PLC based with PC or Panel view Graphical User Interfaces

- Roller rotation speed is adjustable (20-80 RPM)

- Single column overhead beam has collision avoidance photo eyes

- No compressed air requirements

- Ability to be combined with blow off systems for more effective cleaning.

- Blow-off: Using Encore engineered and designed standard machines and robot mounted assemblies Encore offers an extensive assortment of custom blow off systems for a wide variety of vehicle and product sizes. Blow off systems typically fan driven, electro-statically charged, to remove dirt and foreign particles from the surface of parts prior to painting. There are a variety of options on blow off systems, including: Stationary (fixed) or Machine/Robotic. Machine configurations are of various sizes and complexities, High/low volume, high/low velocity air, Compressed or fan driven air, PC based or PLC based visualization systems, PLC based with PC or Panel view Graphical User Interfaces, Clean Wall or In-booth Design, Vacuum collection and/or booth collection of dirt.

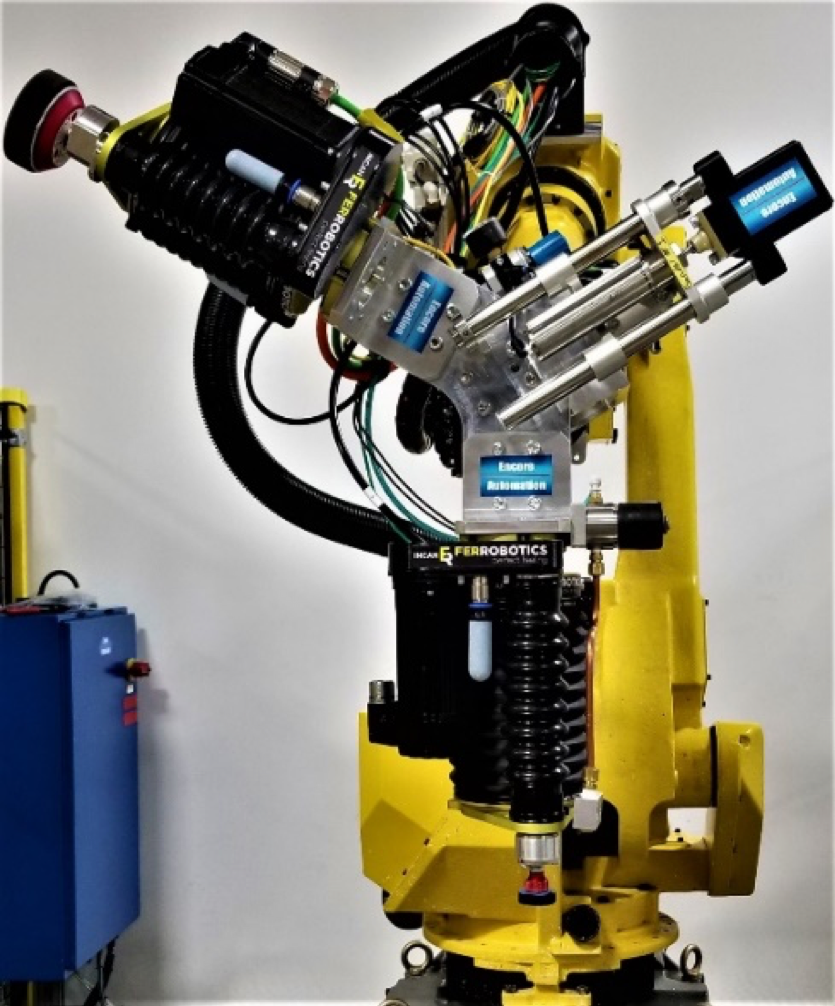

- Sanding & Buffing: Encore robotic sanding and buffing systems utilize the Encore multi-headed tool as well as off the shelf sanding equipment to provide robotic sanding and/or buffing to the full exterior surface of vehicles as well as vehicle components/parts: The Encore system integrates automatic paper changers to remove, replace and validate paper changes. Dust removal systems can also be integrated to remove residual material left behind the sanding process. Encore systems offer automatic tool change capabilities to provide additional flexibility for the sanding process. When combined with defect detection the entire process of seek and finesse can be totally automated.

- Water Blast: Encore water blasting systems utilize off-the-shelf proven technology for water blasting cleaning of carriers and components for a wide variety of configurations and water blasting requirements.

TKS & Encore Automation offer a comprehensive portfolio of surface preparation and surface cleaning systems for any industrial paint line.

Paint Surface Prep Installations & Customers:

Currently in use at:

- FCA: Nineteen (19) surface prep installations

- General Motors, Corvette: One (1) prime wet sand installation

- Harley Davidson: One (1) surface prep system

- The Boeing Company: Two (2) projects

- Fender Guitar: One (1) installation

Automated Feather Duster System

TKS and Encore Automation offer a top-of-the-line automated feather duster system at the entrance of the coating booths. We source and assemble the ostrich feather rolls in-house to ensure quality. The automated feather dusters are equipped with a vacuum system to pull off any debris, dust, or dirt picked up - allowing for continual operation without any maintenance needed.

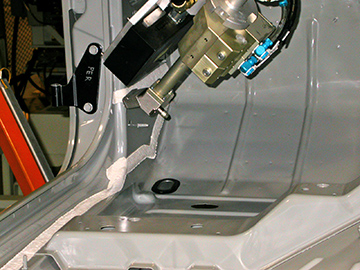

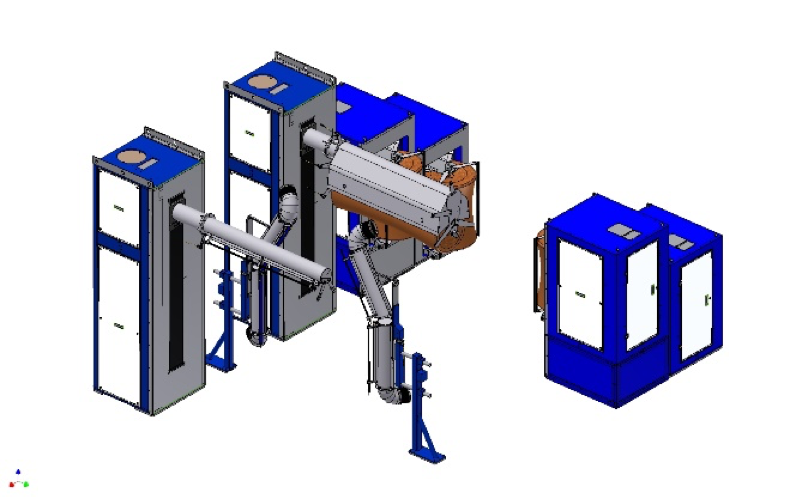

Sealer Automation

Encore offers a complete line of fully-automated sealing products and technologies.

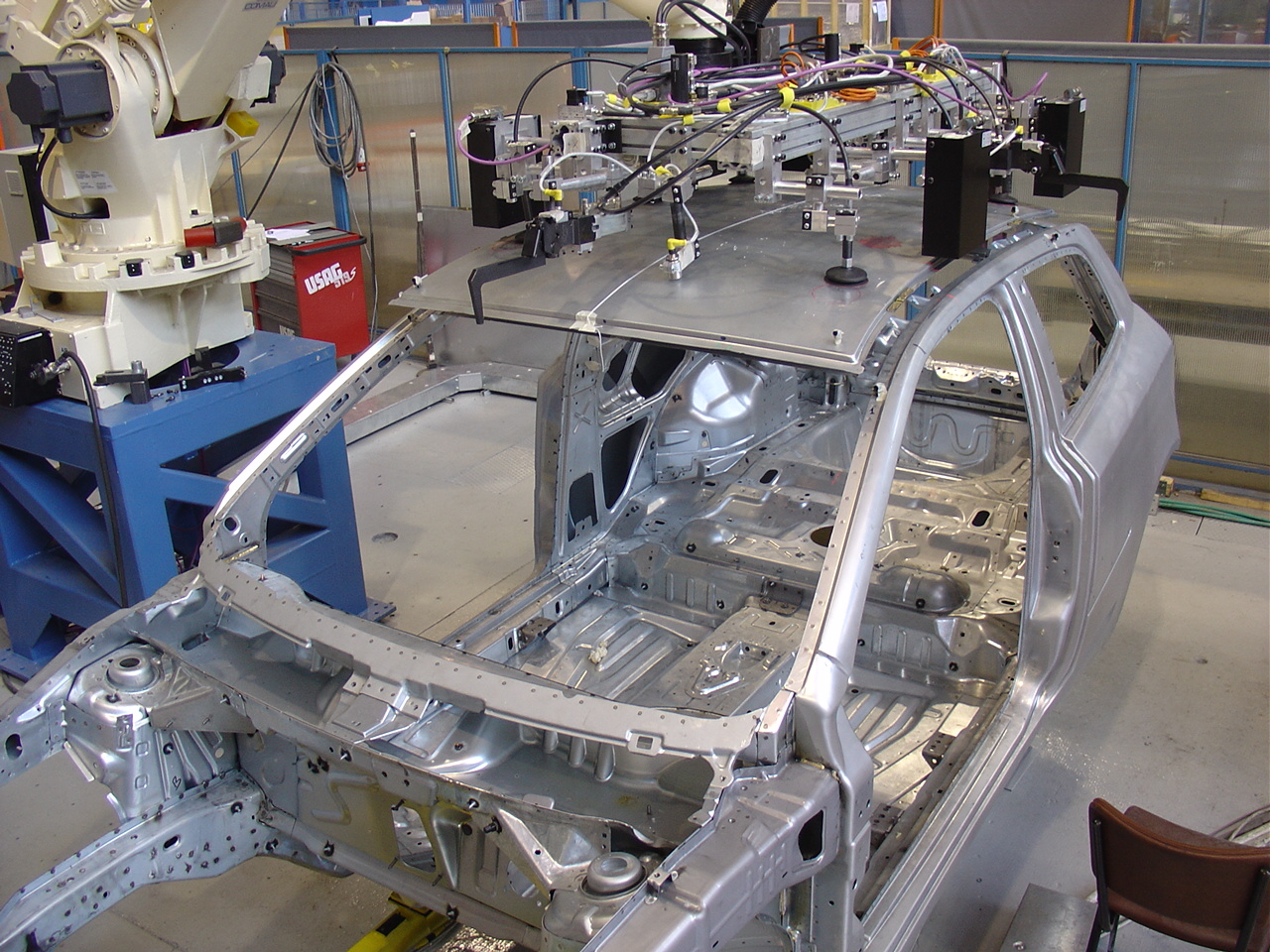

Auto Sealer Cell

Encore has system knowledge and experience to optimally specify, configure, layout, simulate, engineer and design, assemble and test, install, commission, process tune, provide training and service on systems for the above applications and materials for using many of the above equipment options.

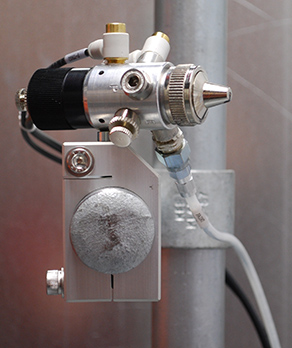

Sealer Application

Sealer Application Approaches including interior Seam, Finesse, LASD, Hem and UBC. Integrated vision systems included fixed cameras and robot mounted cameras. Integration of seam quality vision systems with interactive quality display monitors to help with operator inspection and repair. Turn Key systems with safety fencing, tip dress windows, tip clean off assemblies, support structures, safeties and controls.

Automated Door Sealer

Encore Automationʼs knowledge and experience base allows it to approach many sealing projects and services from a strong foundation.

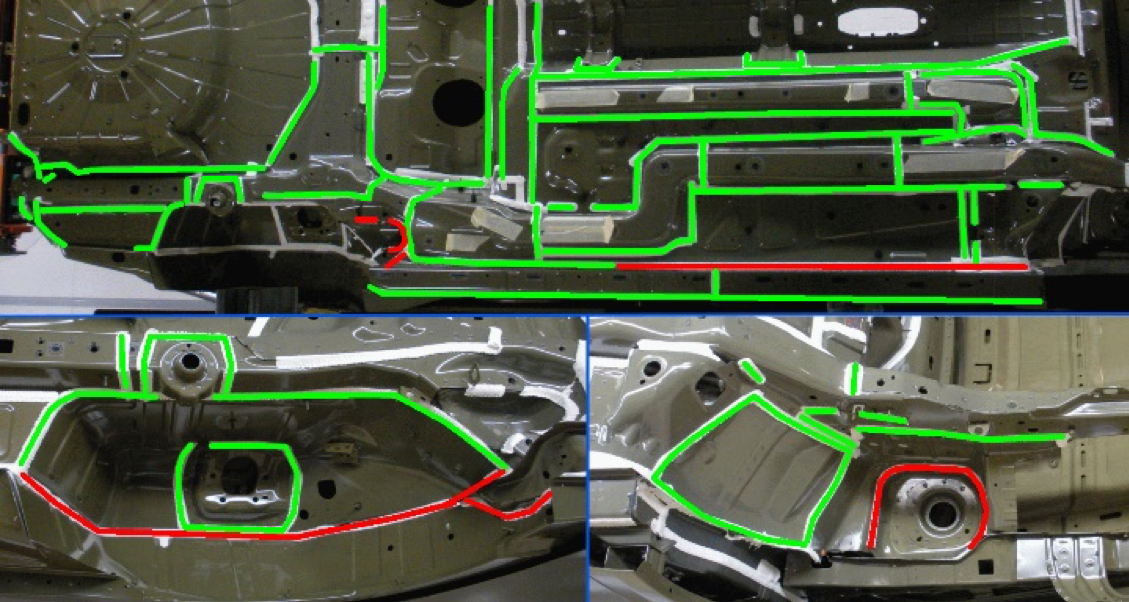

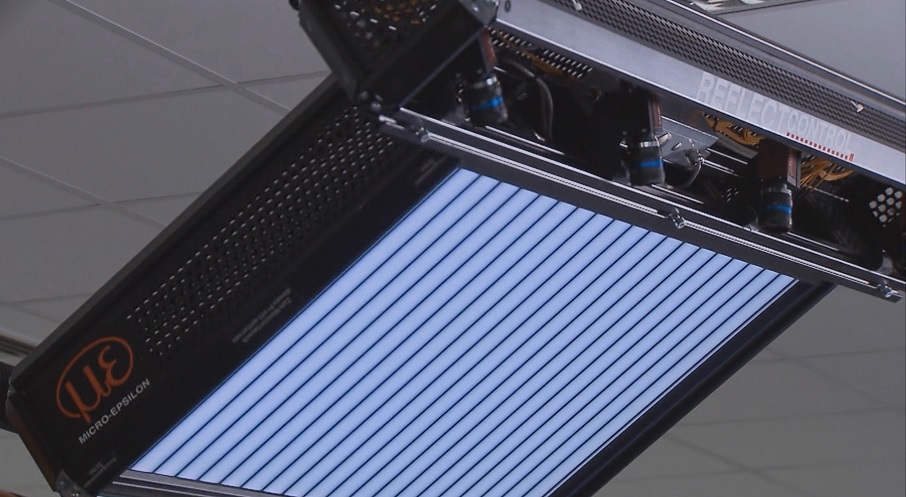

Fully-automated In-line Defect Detection

Encoreʼs defect detection system utilizes a Micro-Epsilon reflectCONTROL sensor that is based on the principle of phase measuring deflectometry to provide robotic defect detection for the full exterior surface of automotive vehicles as well as components and parts.

Sensor for Defect Detection

Fully robotic defect detection systems with multiple configurations depending on production rate and vehicle size. Model specific simulation assures 100% coverage and minor overlap. Signal evaluation optimized for paint defects (<0.3 mm). Automatic defect recognition on all colors.

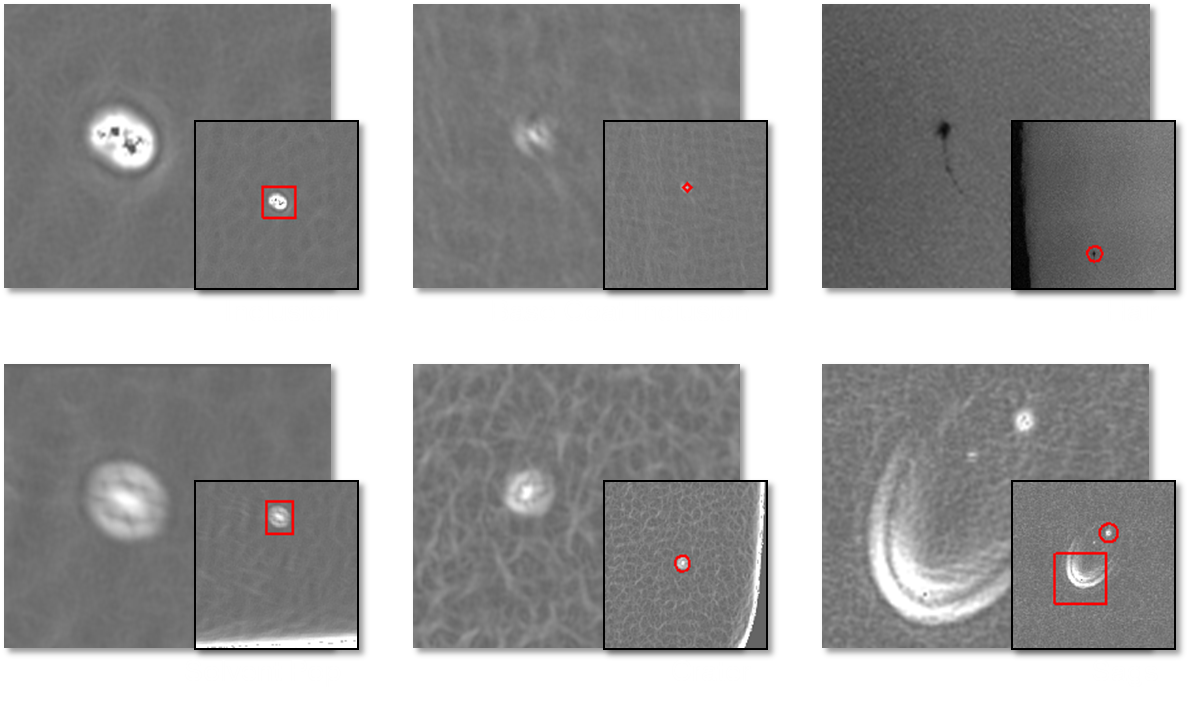

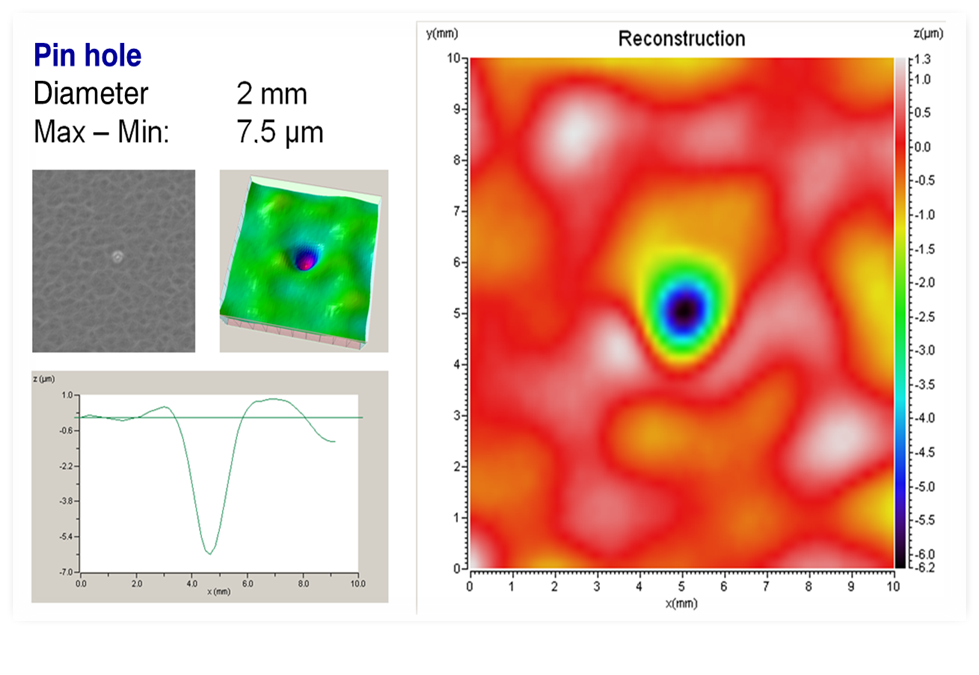

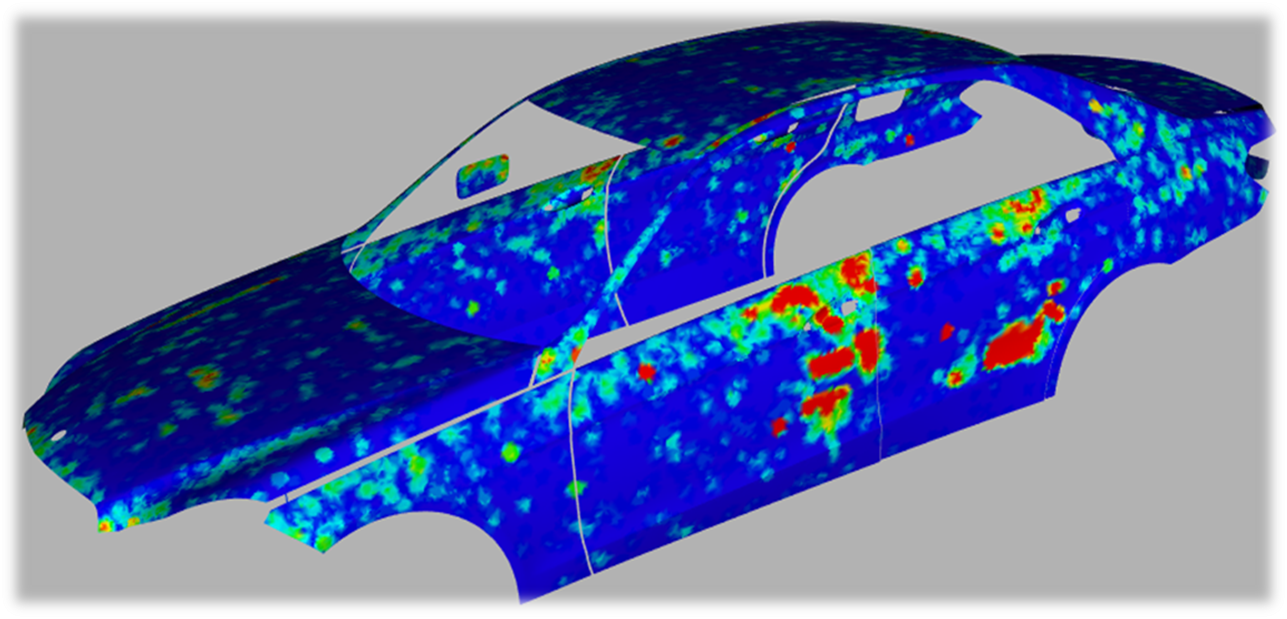

3-D View of Defects

The key differentiator of this type of defect detection system over other vision and detection ysstems is the ability to create a 3-D rendering of the defect, including width and depth of the defect. This information is key to understand which paint layer the defect originates from, and how best to repair the defect. This information can be fed to a robotic sanding and automated finesse system for in-line repair. Encore is the first company in the world to offer a fully-comprehensive, turnkey, automated, in-line inspection and repair system.

Mapping Defect Hot Spots

As an option to the defect detection Encore offers an automatic defect marking system to apply marking material on the defect location as determined by the defect detection system. Fully robotic defect marking systems with multiple configurations depending on production rate and vehicle size. Can be located in a different location downstream from defect detection system, line tracking capability. Applicator and fluid delivery system for marking material.